As leading sports contractors and maintenance providers, our technicians are always up to date with the latest best practice and developments in maintenance techniques.

We are constantly refreshing and updating our fleet of maintenance vehicles and equipment to deliver the very best for our 600 clients across the UK.

Through our experience in the industry, we also know that some of our clients have in-house maintenance teams ready to take on the maintenance of their new build artificial pitches.

We offer bespoke training and guidance on what machinery and maintenance methods will be required to keep your artificial turf pitch or sports court in the best condition, for optimum performance, safety and longevity.

We can even source artificial pitch maintenance equipment on your behalf and run in-person training with your team to ensure they’re informed in the operation of maintenance machinery.

For further details and individual equipment prices please call our Operations Manager Danny Pearce on 01635 34521.

This tractor and brush combination is designed for a regular and efficient brushing regime, crucial to protect the synthetic fibres and prevent infill compaction on a synthetic pitch.

The Speed-Brush is a towable twin rotary brush unit. The brushes rotate against the direction of travel lifting the artificial turf fibres and decompacting the infill material; levelling and preening the surface to leave an aesthetically pleasing, safe finish.

The base rake is ideal for decompacting heavy areas of use on a 3G football pitch, 3G rugby pitch, sand-dressed or sand-filled hockey surface or multi-use games area. The depth of the tines can be easily adjusted to benefit varying pile lengths and infill depths.

The verti-broom has a triangular shape, allowing bristles to ‘bite’ into the surface lifting the pile fibres and redistributing infill material for better pitch consistency.

The verti-groom uses a combination of tines and brushes, de-compacting the infill on a synthetic pitch whilst lifting the artificial fibres.

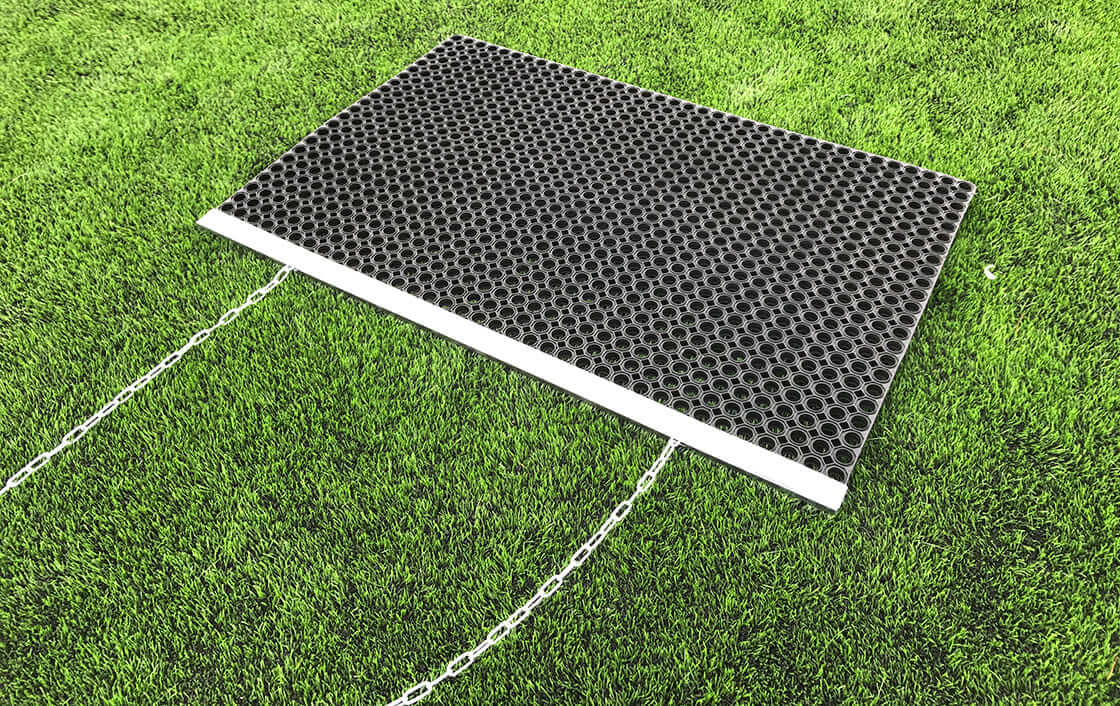

Rubber drag mats are recommended to work rubber crumb infill material into 3G pitches, levelling undulations caused by inconsistent infill levels.

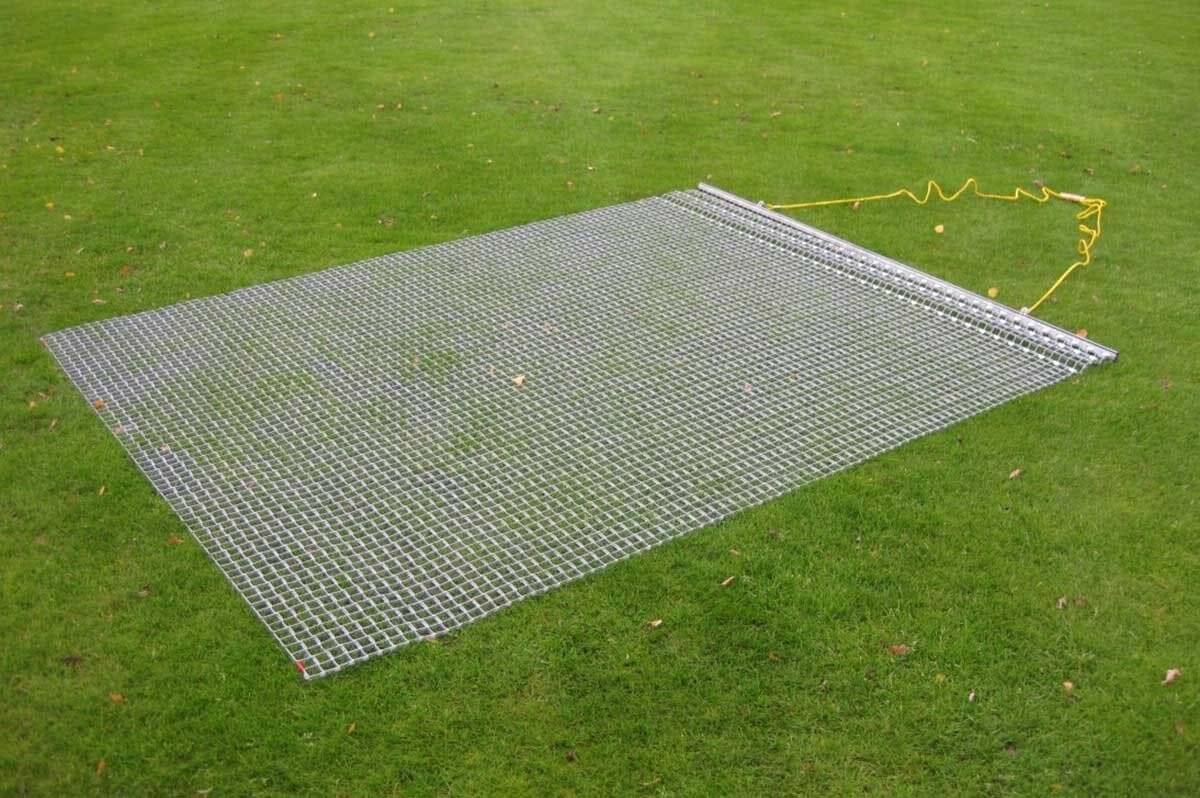

Steel drag mats are recommended for use on sand-filled synthetic turf, working the sand infill into the artificial pile, levelling undulations caused by uneven infill levels.

An infill depth tester measures the infill quantity in a synthetic turf pile. When operated, pins extend down through the infill to the artificial turf backing allowing measurement of the infill depth to be recorded. This tool assists with the management of the system and enables regular readings to check the infill level on your pitch conforms to the specified requirements.

FIFA Quality Performance Standard requires a ball roll of between 8-10m, while FIFA Quality Pro requires the ball to roll no further than 8m.

A ball roll ramp allows you to check the level of resistance the artificial surface gives to the ball when it rolls across it. If the ball roll exceeds the FIFA standard figures, it’s a good indication that additional de-compaction and brushing of the surface is required.

There are a number of other maintenance products we are able to advise on and source that aren’t listed above.

Please contact us by giving our maintenance operations manager Danny Pearce a call on 01635 34521 or email dpearce@sandcslatter.com to discuss what options would be best suited to the needs of your pitch or court.

For more information call 01635 34521 or email enquiries@slattersportsconstruction.com