The Slatter Group team has grown over recent months, so we’re taking the opportunity to follow up with our latest recruits, getting an insight into their role and experience, whilst welcoming them to the team.

Tom Betts recently joined our Design and Planning department as Project Designer / Consultant, bringing with him a wealth of experience.

Busy and exciting – turning my attention from project consultancy to pre-construction development has been great fun – with lots of support from new colleagues with much experience and insight.

I joined the sports construction industry in September 1994, so I have worked within various functions and disciplines and with growing responsibilities for 25+ years.

My competency and talent has matured over this time which has helped me to accept and solve more complex project requirements and changing demands.

I am very much fascinated by the evolving nature of sports construction and facility design, contracts, development control, and procurement. So, I suppose this curiosity drives me to persistently check, review, adjust and improve my service offering to clients.

My role is Project Designer / Consultant, so I am tasked with developing schemes for clients from conception to build-readiness, then to be installed by our sports construction teams.

There are many interconnected processes required to convert an idea to construction-capable plan, so our constant challenge is to simplify this journey for our clients whilst making certain that all checks and balances (quality, cost, time) are achieved along the way.

The size of pitches, courts and tracks have changed little over 25 years, but substantial modifications have been seen in respect of surface technology, substrate preparation, and drainage engineering, as well as a host of ancillary items.

Testing and compliance activities have evolved during this time too. I think many inventions have been brought forward to address the genuine need to create artificial sports surfaces that perform more faithfully (and reliably similar) to natural turf, whilst other innovations are motivated by a wish for improved efficiency and economy. Very recently, innovations have turned towards sustainable recycling techniques and micro-plastic reduction, both being at the heart of responsible turf manufacturers, like our partners FieldTurf.

Concerning the planning system, I remember in the mid-90s there was some scrutiny that was justly applied to developments seeking planning permission; and this attention has grown over time and now covers wide-ranging proposal aspects (almost every part of a proposal). Fairly so I think, given our better understanding through experience of the potential impacts that a facility could create. It has always been essential to ensure any project is compatible with its surroundings and this assessment should begin at the earliest definition stage, even if this sometimes results in a changed brief and a more realistic option.

We have quickly become more conversant with technology to help us continue work remotely. This does have some advantages and reminds us that various types of interaction and meetings can take place very conveniently even if they are virtual. Naturally, our sports construction teams took stock when coronavirus pandemic arrived in the UK, to understand how this affects construction sites and to plan for safe working.

Thankfully, we are now largely working to full effect; having organised our works and services, our manufacturing, and our construction activities, acknowledging all necessary safety recommendations and social distancing requirements and in accordance with HM Government recommendations.

I don’t think this has ever changed – good guidance and leadership to help navigate a project through a variety of perhaps unfamiliar sequential stages with confidence and trust. Clients rightly want honesty, expertise, diligence and not necessarily the cheapest provider, but certainly best value.

Awareness, intervention, and judgement. We must stay an authority within this specialism to offer our clients the right advice, and take the right actions, at the right time.

For sports construction, designing and securing planning permission are dynamic situations; so an intricate knowledge of due process, potential opportunities and pitfalls is essential to properly steer any project and satisfy our clients’ objectives.

S&C Slatter is a successful and ambitious company with excellent resources and integrity at its core. I am attracted by these qualities and spotted an opportunity to strengthen our design and planning service. With my consultancy background, I really appreciate clients’ needs and can add this problem-solving attitude to our team.

I’m very into football, as an FA qualified coach and HTFC U12/U13 football manager. I also enjoy spending time with my family and playing music – particularly playing the drums.

Thanks so much to Tom for taking the time to do this Q&A with us, we’re thrilled to have him join us as Project Designer / Consultant – welcome to the team!

Our design and planning team will provide expert advice on what’s possible on site, and the best way to achieve your goals.

If you’re considering a sports construction project, and want to work with one trusted point of contact – from design and planning through to construction and aftercare – get in touch with Tom and the team on 01635 345 21 or email info@sandcslatter.com.

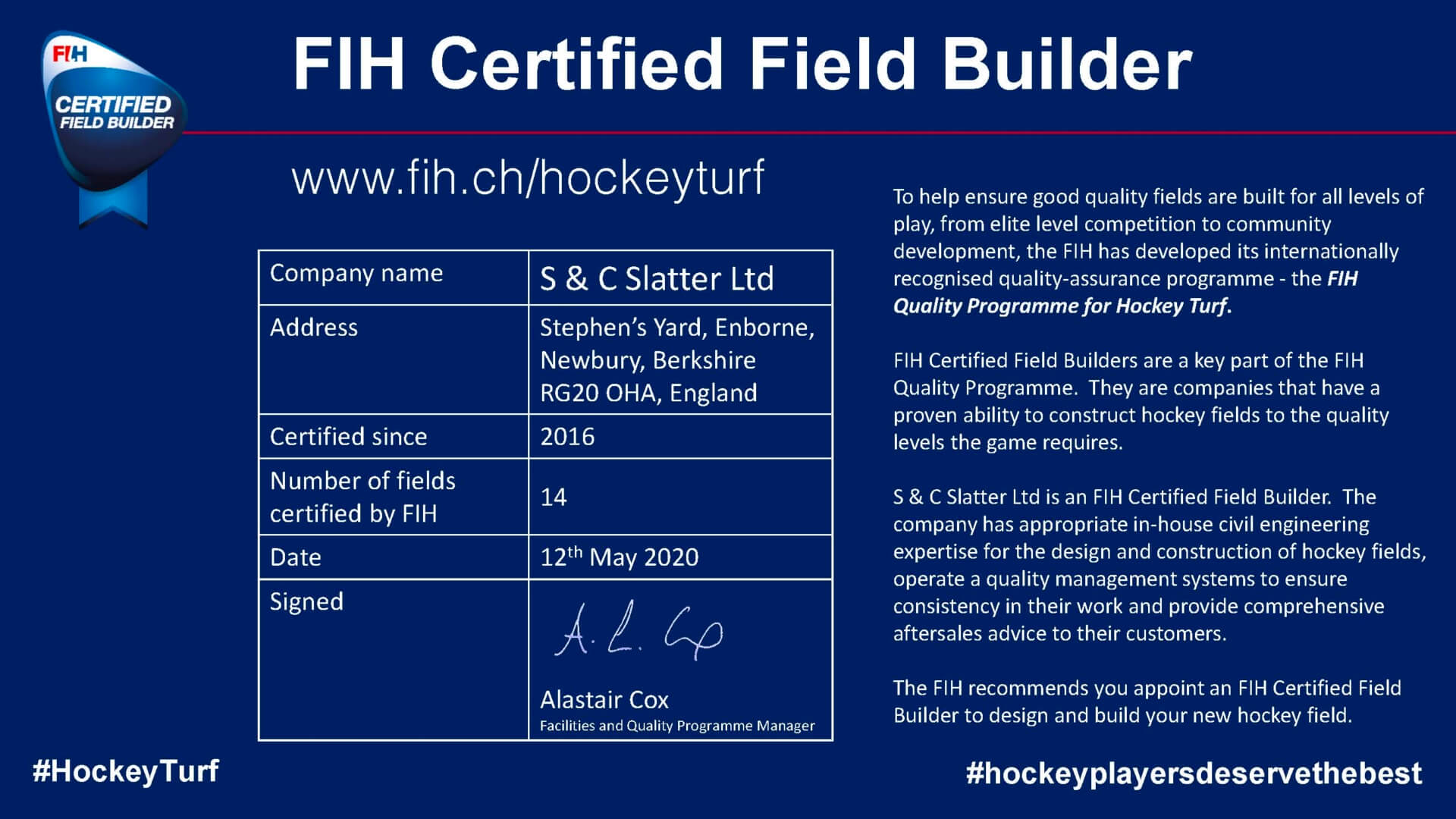

Under the 2020 FIH Quality Programme for Hockey Turf, S&C Slatter has once again been certified as an FIH Certified Field Builder.

FIH Certified Field Builders must demonstrate proven ability to construct hockey fields to dependable industry standards worldwide, ensuring the appropriate quality for the intended level of play.

As the first contractor globally to be recognised as an FIH Certified Field Builder back in 2016, we’re proud to have retained our certification annually since then, proving our commitment to FIH’s aims and objectives in the global development of hockey.

To be certified under the programme, organisations must provide evidence of in-house expertise, experience and commitment to hockey. This includes, among other things, proof of in-house civil engineering expertise, environmental policies, ISO 9001 Quality Management System accreditation and comprehensive aftercare advice for clients.

At the launch of the programme, Alastair Cox, FIH Facilities Manager stated that the FIH Quality Programme for Hockey Turf is:

“a fantastic opportunity for suppliers, manufacturers, field builders and field owners to become part of an official quality-assurance programme. In doing so they can be confident that their field performs correctly, is safe, built to specification and maintains performance”

Without the comfort of engaging with a certified field builder or certified turf supplier, you have no such guarantee.

The construction of a synthetic turf hockey pitch is a specialist trade, requiring expertise and experience to avoid risks associated with sub-standard pitch design and construction.

If unsuitable materials are used in the base construction of the pitch, drainage and surface levels could be compromised, leading to a surface that’s unsafe to play on, becoming waterlogged and slippery.

The same goes for the surface too. Using a low quality, cheap artificial turf that isn’t under the FIH Preferred Supplier or Certified Manufacturer programme could result in inconsistent performance and premature failure, which will be more costly overall to replace.

The International Hockey Federation (FIH) launched the Quality Programme for Hockey Turf in 2015, “as part of a 10-year strategy that aims to make hockey a global game that inspires the next generation.”

The programme introduced the levels of certification we know today (Global, National and Multi-sport) as well as Certified Manufacturers, Certified Field Builders and Preferred Suppliers.

We’re proud to be FIH Certified Field Builders and have delivered the highest number of pitches in the UK to be certified to FIH Global performance standards, including Reading Hockey Club and The University of Warwick.

Working closely with our exclusive artificial turf partners FieldTurf, who are FIH Preferred Suppliers, we’ve seen first-hand the great impact the FIH Quality Programme has had on the sport. We look forward to continuing to support the programme, delivering first-class hockey facilities in the UK for generations to come.

The FIH recommends that you appoint an FIH Certified Field Builder to design and build your new hockey field.

Get in touch with our team for a free consultation.

Next up in our Q&A series with our newest recruits, we welcome Yasmin Taylor, who joins us as Buying Assistant, and has a great family history in the industry!

Hello, thank you!

I have really enjoyed my first few months, as I am back doing what I enjoy most. The team are great and have encouraged and helped me where necessary. A couple of times I have questioned myself (which I am pretty certain is normal in a new company!) but have persevered and my confidence and independence is growing day by day.

My role is Buying Assistant. This includes assisting the lead buyer with placing orders, liaising with Contracts Managers/Site Managers to ensure materials are on site in time (and on budget), and preparing O&M manuals post project completion. I work alongside Simon and think we make a great team. We are always looking at ways to make improvements and maintain an efficient working environment.

Having left school, I completed an apprenticeship at West Berkshire Council. I felt this was definitely the right move for me, as I enjoy learning hands-on as opposed to through full time study.

The contract was for a year, in which I completed my NVQ level 3 in Business Studies. During that period I was nominated for Apprentice of the year by several other employees/teams.

At the end of that apprenticeship, I decide to apply for a few positions, one of which was within the council (which I secured), but after an interview with a local company close to home, I decided to opt for that position. It seemed challenging and would add another string to my bow, in regard to learning purchasing. I worked there for 3 years, before deciding that I wanted to progress further and learn alternative skills.

I was then employed by a local company as a Customer Service Representative. I felt I grew quickly within that position and always had a positive rapport with customers and work colleagues. The company was large and spread throughout Europe and China. We worked closely with our neighbouring offices and I enjoyed my time there, but I knew quite quickly that I was happier in procurement/buying, which is when I decided to pursue a position back in that field. I think this stems from my background as both my parents and grandfather have worked in this sector for most of their careers.

We have all dealt with major changes over the last few months. For me, I have been able to carry on working (from home) which I have found straightforward. All calls forward to my mobile, a laptop was supplied for me to be able to continue working (very much appreciated!) and things have pretty much carried on as ‘normal’ as they can be.

I would say everyone has adapted to the situation well, we have kept in constant contact, making sure that everything runs as it should daily and I feel we have built up a strong working relationship through these very challenging times.

For me, it’s relying on other sectors to be able to fulfil my role. Some suppliers have had to temporarily close, whilst others are operating with a skeleton staff, meaning that not everything we need to complete projects has been so readily available. At times this has been challenging, but everyone is in the same boat so to speak and their understanding has been amazing.

From the minute I walked into my interview, I loved the fact that S&C Slatter was an independent family run business, thriving in a very competitive market. Knowing the Buying Assistant role would give me the opportunity to get back to buying/purchasing was a massive bonus and the people I work alongside have been most welcoming, it really is a great place to work.

Having purchased our first home in May last year, we have spent a lot of time revamping and modernising the property. We are finally at the end and now have more free time to enjoy bike rides, movies, socialising with friends (well, we did!) and have just purchased our first dog, a Springer Spaniel, uh oh!! We will train him as a gundog to enjoy partaking in our local family shoots and long walks through the countryside.

Thanks Yas, we know you and Simon are busy ensuring the team have what they need on site, so thanks for taking the time to do this Q&A with us – welcome to the team!

With £3m of wholly owned and operated specialist equipment, we’re ready to deploy our teams on site, with our procurement department ensuring we have the materials and additional equipment we need to deliver your project to the highest possible standards.

If you’re considering a sports construction project and want to ensure maximum quality with minimal risk, get in touch with our team on 01635 345 21 or email info@sandcslatter.com.

As The Slatter Group continues to expand, we’re following up with our newest recruits, taking the opportunity to welcome them to the team whilst getting an insight into their role and experience.

Andy Bingham joined our busy sales & estimating team as an Estimator in late March, bringing with him comprehensive experience in estimating – from light bespoke civils projects up to large scale main contractors’ projects.

Hi! Well they’ve been very busy actually, the sales team has generated a lot of leads and we’re on the radar of a lot a Sports Consultants so there has been a whole range of tenders to get stuck into. I’ve even managed to get out to the Channel Islands (I wasn’t expecting the ‘international travel’ side of things so soon)!

To be honest though, I’ve more or less had to find my feet immediately, which is no bad thing – as it shows the company is being very pro-active about moving forward and securing work! Also I guess it means they trust my judgement which is comforting.

I’ve still got some names to put to faces and faces to names, along with systems to understand – so it’s still early days.

My background is predominately in macadam surfacing and light groundworks having worked for a well respected Surfacing Contractor. I was in this role for nearly seven years moving up through a Management Trainee scheme in which I gained valuable onsite first hand experience and supervisory skills. Thereafter I fell into the role as an Estimator and CAD Technician / Design. I had some working knowledge of CAD and GPS surveying equipment from a ‘Year In Industry’ that I undertook after college; working within a Hydrographic Surveying Office at the Port of Poole prior to obtaining my degree in Civil Engineering.

I utilised these skills to help formulate proposals and design drawings for light bespoke Civils schemes in a way that our competitors (at the time) were not.

In the year prior to joining S&C Slatter, I worked as an Estimator for a Main Contractor which gave me a broader view on pricing and higher value projects.

It feels like I’ve joined an already ‘well oiled machine’ – there’s an incredibly strong work ethic and my colleagues have wealth of knowledge and understanding of the industry.

My role as Estimator is predominately involved with the completion of tenders at this stage, coupled with site visits (of course!) to confirm there is nothing untoward within proposals.

There seems to be a slow but steady drive towards more sustainable practices which is great to see; many tenders now seem to target offsetting new construction with some form of ecological enhancement to the nearby area. It’s good to see this becoming part of the focus rather than an afterthought.

Obviously Health and Safety is something that has also come on leaps and bounds even in the 10 years that I’ve been working! Our new Health and Safety Manager (Nick Jordan) seems to be very pro-active and works to ensure our internal documentation and processes are always up to date.

Working remotely for site-based staff is obviously not ideal – however in our particular niche of the industry we are seeing some return to normality.

As you know much of our works are relatively isolated and contained within themselves, meaning our operatives do not have to come into regular close contact with others, thus it is relatively easy to stick to the two metre rule!

Deliveries of materials from our suppliers also sort of fall into that category of limit contact as well. Suppliers are implementing policies like remote delivery signing that avoid direct contact.

On our side of things (Estimating & Sales) – we are largely able to work remotely, so the main adaptation really is lack of face to face office contact and the normal sort of discussions that you may have in the office. Its not quite as easy to ‘pick someone’s brain for a second’ remotely! Site visits have also ceased presently for future tenders unless they can done without breaking contact guidelines – this poses its own challenges in making sure that the site conditions are assessed correctly when pricing.

I guess also one of things I’m having to adjust to personally is the lack of physical paper drawings… I’m used to having a large A3 / A1 site plan in front of me, so getting used to not having that element easily available had to be a quick adjustment – but this is one thing the industry was already trying to tackle before lockdown. Many businesses are moving down the route of ‘paperless policies’ which really is great to get onboard with. I’ve seen first-hand how easy it is to print to the A0 plotter and waste unnecessary amounts of paper by accident!

I think as we run the risk of sliding into a recession, customers will be faced with even tighter scrutiny on spending and future budget allocation. Contracts are generally awarded on a weighted basis towards cost, with quality practices considered thereafter. So the pressure will be on the clients to go with the cheapest option.

As a business, we work hard to demonstrate value for money in every aspect of the build, ensuring quality is not compromised. Another way the company is seeking to support clients is through providing guidance on what financial solutions are available to help fund all or some of a project, and avoid cost cutting at the expense of quality.

Our installations are second to none, and offer the longevity and aftercare policies that set the higher standards for the industry. When a client looks at return on investment then we generally do well.

I think assessing that everything has been included, that there are no unknown elements to a scheme that could result in extra cost. You never want to price a job that will lose money. So really it’s just about being as thorough as possible within the time constraints allowed. I need to work on the time constraints side of things!

It looked like a young vibrant company; and after being approached by Ben following my previous experience, it sounded like an interesting role. S&C Slatter’s portfolio of work is very impressive!

Speak early on in the process with our Sales teams who will work with our design and planning department to provide good advice, Nick and Josh will help draw up some sensible proposals!

Up until lockdown I was playing regularly in a band.

The writing and recording side is still going, although I haven’t had much of a chance recently believe it or not! I’m not sure really what the future holds for that side of things as the live element is non-essential and hard to justify at this current time – the impact of the virus really has hit that industry hard!

Thanks so much to Andy for taking the time to do this Q&A with us, we know it’s a busy time for the tender department and know he’s been a great asset already – welcome to the team!

Our estimators are on hand to give you the best possible understanding of what’s possible on site, and at what projected cost.

If you’re considering a sports construction project and want to ensure maximum quality with minimal risk, get in touch with Andy and the team on 01635 345 21 or email info@sandcslatter.com.

Following on from our article last week on how schools and leisure facilities can prepare for life beyond coronavirus, we’re thrilled by the Football Foundation’s announcement of their new Pitch Preparation Fund. This will enable Football Clubs and small leisure trusts to be game-ready for when the lockdown is lifted.

The Pitch Preparation Fund is a new fund launched by The Football Foundation, the charity created by The Premier League, The FA, The UK Government and Sport England to deliver football grants.

The fund itself has been created to provide ‘financial support to those struggling to maintain their football pitches across the country’. It’s to help clubs and organisations to get their natural or artificial grass football pitches ready for when the lockdown is lifted, so that both play and revenues can get back on track as soon as possible.

The fund can be used to cover the cost of either natural turf maintenance such as aeration, line marking and grass cutting, or for 3G artificial turf maintenance, such as deep cleaning, FA pitch testing or seam repair.

Just under £10m has been allocated to the fund (£9.56 million to be precise) which has been estimated to benefit roughly 4,000 organisations nationwide.

The Pitch Preparation fund is open to grassroots, local and national league level football clubs in England, Premier League clubs in Wales and small leisure trusts.

The Football Foundation have stated that “Every applicant must be a club or organisation with a minimum of 12 months’ security of tenure over the pitches they wish to improve by freehold, leasehold or licence, and have the legal responsibility for maintaining them.”

The full list of eligible and ineligible organisations can be found on the Football Foundation website.

The maximum grant you can apply for depends on your organisation type and number of pitches and will vary between a maximum of £1,500 – £5,000.

If you’re a National League System Club (Step 1-6), FA Women’s Pyramid Club (Tier 1-5) or Welsh Cymru Premier League Club, you can apply for up to £1,500 for a Stadium Pitch grant.

If you’re a grassroots club or organisation, you can apply for:

S&C Slatter are, with our artificial turf partners FieldTurf, one of a few select approved construction and maintenance partners serving the Football Foundation.

Already successfully supporting our clients across the country with professional maintenance of their 3G Turf pitches, our expert support will now extend to helping you with your Pitch Preparation Fund application.

As well as supporting you with your grant application form, we’ll undertake a free assessment of your pitch condition prior to works commencing, to help you identify the most efficient use of your grant.

Please get in touch by calling our Project Manager Matthew Thompson.

Tel: 07584 666548 Email: mthompson@sandcslatter.com

The closing date for applications to the fund is less than two weeks away – applications must be submitted by 9pm on Monday 25th May.

This fund is a fantastic way for eligible organisations to get their pitches up to scratch ready to provide sporting facilities to those that will need them beyond lockdown.

If your organisation is eligible and would free like assistance in your application to the fund, please don’t hesitate to get in touch with us.

With health & safety high on the agenda for everyone during these unprecedented times, we thought we’d check in on our new Health and Safety Manager, Nick Jordan, for a quick Q&A to hear more about his background and his thoughts on the rapid changes happening in the sports construction industry.

Nick joins the company with extensive experience and qualifications in the world of health & safety – whilst also having a unique perspective on our industry from the other side – as a former professional football player!

Thanks, to say it’s been busy would be an understatement! No one could ever have predicted the situation the country has found its self in and I definitely didn’t expect it when I joined the company 10 weeks ago. Although the situation has not been ideal there have been many positives to take, for me it has proven why this company has grown so quickly and so successfully.

In a time where there has been so much uncertainty in the world there has been a clear message from David Slatter and the team – and that was if we stick together we will come through this pandemic stronger. Throughout the 10 weeks I have received nothing but support from within the business and feel I have already formed strong relationships with many individuals involved with the business. It has been extremely humbling and I am excited for what the future holds for S&C Slatter.

I am a retired professional footballer and decided to hang my boots up at the age of 22. From there I put myself through university as I was unsure where life would take me, football was all I had known since I had left school at 16. I studied Sport and Exercise Science at the University of Portsmouth whilst I was assessing where I wanted to take my career. In my final year I took the bold decision to leave and pursue a career in construction where I joined Dyer and Butler in 2014 after receiving my Higher National Diploma (HND). At Dyer and Butler I was quickly given the opportunity to progress through the ranks and I was fortunate enough that the former Health and Safety Manager offered me a position as Assistant Health and Safety Advisor. Dyer and Butler funded an extensive selection of courses which allowed me to become qualified in several fields very quickly, then backed my progression throughout to allow me to become a fully qualified Safety Professional with a large portfolio of nationally recognised qualifications.

My role within the business is Health Safey Environment Quality and Training Manager. Ultimately I am responsible for all employees’ Health and Safety – not only on site but within the office setting. Another responsibility is to identify areas of improvement and to assess individuals, identifying courses which will up-skill our staff. This in turn improves our business so that we can provide the best complete service whilst ensuring the highest level of compliance on site.

Everyone in the industry will agree there have been huge changes within the industry over the past few years and (depending on who you ask) you will receive different answers as to whether they agree on all those changes. The biggest change I have seen is that the HSE and the other enforcing bodies have started focusing on occupational health and have introduced large sanctions on companies that fail to manage this. This has been brought about by the number of claims from the older generation that used to undertake tasks such as breaking/grinding out brickwork and concrete without sufficient controls measures in place.

Over the past few years scientific evidence has been brought to the table to highlight the heath implications of not managing construction risks. Illnesses such as Silicosis/mesothelioma and white finger have started to become evident in the older generation of construction workers and this has led to the enforcing bodies focusing their attention on these areas. Companies now are mandated to ensure that staff undertaking tasks are adequately protected with sufficient control measures implemented. You will see far fewer operatives in the future suffering the same injuries and ill health as the previous generation, which is a positive change.

The HSE have been quiet throughout the pandemic which has surprised me as they are usually at the forefront of providing advice. Whilst many assume that The Health and Safety at Work Regulations may have been relaxed like MOT’s etc, they have not. The Regulations were introduced to ensure the safety of staff and there has been no changes in the regulations due to COVID-19. What has been introduced is the Site Operating Procedures issues by the Construction Leadership Council. This document provides guidance on what is expected of all sites that have to continue to operate.

Having only been at S&C Slatter for a short duration of time – the majority of which has been been under lockdown – I haven’t yet dealt with many challenges customers are facing. From past experience, for me it would be companies fully understanding their roles and understanding their duties under the Construction Design Management (CDM) Regulations 2015. Where the CDM Regulations 2015 are extensive and so in depth, company’s representatives do not always fully understand what is expected of them and that is often challenging when delivering projects.

My role as a Health and Safety Manager often poses many challenges – not necessarily within S&C Slatter, but for Health & Safety (H&S) professionals across the board. The biggest hurdle is getting the buy-in from the teams on the ground delivering the work. Due to Health and Safety often presenting hurdles during the construction phase, you sometimes find that the team delivering the work will respond negatively to healthy & safety procedures, as they see them as a hinderance if their works are held up. This is where building strong relationships is crucial. If teams feel they can call you for advice and involve health & safety throughout the whole process, any negativity is removed. At S&C Slatter as stated above, I have been welcomed in my role, which has made my transition into the business smooth.

When I was approached regarding the role I was told that S&C Slatter was a company that were growing quickly and had a young team that were hungry to succeed and progress. When I sat down with Ben O’Connor and Peter Fowler, they outlined exactly where the business was and where they intended to take it. The hunger to succeed matched my ambition so I was sold almost immediately following our discussion and couldn’t wait to join.

From a Health & Safety perspective I would recommend the individual responsible for health and safety within any organisation being involved from the planning phase. This allows for a different perspective and can often lead to major hazards being removed or risks being reduced before construction has even begun.

With having a young energetic family, we are often out on dog walks or bike rides as my kids love to be active. We have been renovating our home for the last 18 months so any free time is eaten up working on the house.

A huge thank you to Nick for taking time out to answer these questions – we know how hectic it is for him at the moment – and what a brilliant insight into the changing and important world of health and safety. Welcome to the team Nick!

Putting the safety of our staff and clients is at the forefront of what we do. Every project we undertake involves our dedicated health and safety manager, contracts managers and site managers to ensure best practice is delivered on all of our sites.

If you’re considering a sports construction project and want to ensure maximum quality with minimal risk, get in touch with Nick and the team on 01635 345 21 or email info@sandcslatter.com.

“Stay Home”. It’s a phrase we’ve heard countless times, and a way of living that we’ve all become accustomed to over the past 6 weeks.

Thankfully, one of the few exceptions allowing us to leave our homes is for physical activity – albeit once a day. But with Sport England showing a record high in activity levels in the 12 months up to November 2019, how will the Coronavirus outbreak and restricted access to sports services affect the nation’s fitness, and what can be done to keep activity levels up?

The first step to keeping these activity levels high – for both adults and children – is to promote physical activity that can be carried out during the lockdown, to ensure that habits maintained (or formed) and more likely to continue after lockdown.

Sport England quickly responded to the lockdown measures by launching Stay in, work out, a great pool of resources for keeping active at home – but won’t necessarily quench the thirst of those missing their favourite team sports.

Why not opt for something more personalised and put together some practice drills for your school’s hockey team, or for those members of your leisure centre that miss their weekly kickabout – Why not email out some training programs to improve their skills and whet their appetites for when you reopen?

A leading sports contractor for nearly 30 years, we have built in excess of 60 sporting facilities over the last three years, and in ordinary circumstances we deliver pitch maintenance programs at over 600 locations.

As sports providers look to the end of Lockdown, one of the questions being asked is “how do I make sure my pitch is thoroughly clean?”

In conjunction with manufacturers of disinfectants, cleaning products, and artificial sports turf we’ve been looking at the best ways to ensure pitches are clean, safe, and ready to go as lockdown restrictions ease. Contact our Operations and Maintenance Manager Danny Pierce to learn more on 07498 826 885 or email dpearce@sandcslatter.com.

Speaking to our clients, we know that there remains a strong desire to improve the sports services and facilities available across the education and leisure sectors but there is a common challenge – funding new facilities.

Before the pandemic many organisations had plans and funding in place for the development of new sports pitches and grounds. While the ambition to bring these projects to life remains, the reality of uncertain finances is a significant challenge in commencing work.

Many schools may be unaware of the finance and leasing options available to them. There are dedicated funding and leasing opportunities available for sports construction and refurbishment projects which will enable you to spread the cost of improving your sports facilities. To learn more get in touch with Jason Douglass on 07786 987 215 or jdouglass@theslattergroup.com

When the lockdown was implemented in late March, guidance was unclear for how construction companies should proceed. We took the decision to safely shut down our sites immediately, as we felt it was the most responsible course of action to take until the situation became clearer.

Following a three-week shutdown period, new guidance from both the government and Construction Leadership Council was published, with the industry developing a well thought out set of site operating procedures, signed off by Public Health England. With these new procuedures in place and a clear directive from the government to keep construction work going through the UK lockdown, we began a gradual re-opening of sites, working with leisure and education facilities to construct, improve and maintain their sporting facilities.

These sites have been carefully chosen by our Contracts Managers and Health and Safety Manager, who worked tireless through our shutdown period to implement new ways of on-site working that comply with social distancing and safeguarding procedures for travel and work.

With Sport England showing that activity in schools stagnated between 2017-19 and UK Active showing that visits to leisure centres fell 5% between 2017-19 now is the time for schools, universities and leisure centres to improve their sports services and make an active nation a positive outcome of the pandemic.

If you’d like to discuss improving your facilities ready for pupils or members beyond the UK lockdown, please get in touch.

The Slatter Group (incorporating S&C Slatter and White Horse Contractors) are thrilled to announce that our Group Director Jason Douglass has joined the board of SAPCA as Chairman of Pitch & Track Divisions.

SAPCA is the Trade Association for UK Sports and Play Construction, working towards building an active nation with a goal to “ensure that every project meets the customer’s expectations, is designed, built and maintained to last, whilst delivering excellent value for money.”

As SAPCA members for a number of years, we’ve seen first-hand the benefits of SAPCA’s work for both customers and members. The SAPCA team have decades of experience supporting organisations from across the industry, promoting the work of suppliers and contractors, providing education and thought-leadership events to ensure members are up to date in the latest industry developments.

For customers, SAPCA provides guidance across the sport and play project journey, from getting started with funding and planning through to construction and maintenance.

Jason joins a 12-strong SAPCA Board as Chairman of Pitch & Track Divisions. His role will include the ongoing promotion of SAPCA and its important work for members, to represent the views and opinions of the Pitch and Track division members and to actively support the implementation of SAPCA’s 2020 strategic review.

“I’m proud to accept the invitation to join the SAPCA board as Chairman of Pitch & Track Divisions. SAPCA play a pivotal role in our industry as educators, thought leaders and best practice advocates. I look forward to contributing my substantial experience in the sports construction industry to the team…” – Jason Douglass

Jason’s wide-ranging experience in the sports construction industry will undoubtedly prove to be an asset to SAPCA’s work, championing innovation, the need to address environmental challenges and ensuring the voice of division members is heard.

If you’d like to learn more about Jason’s role on SAPCA’s board, or are simply looking for guidance on a sports construction project then please get in touch.

With extensive experience in constructing World Rugby 22 Regulation certified elite rugby pitches, we work closely with our artificial turf partner, FieldTurf, to deliver world-class surfaces for our clients.

We’re thrilled to share that today FieldTurf has announced its partnership with Richie Gray as Director of Player Experience for Rugby.

With coaching experience across some of the world’s top teams, Gray is currently Skills/Contact Coach at Montpellier Herault Rugby in France and has a wealth of knowledge in the sector. With his elite coaching systems utilised by top teams across Rugby Union, Rugby League and the NFL, his insight and dedication to innovation will be an invaluable asset to the future of artificial sports turf.

The announcement forms the launch pad for FieldTurf’s new Rugby-centric innovation program – Scrum 2.0 – focused on better understanding the needs of players in order to deliver rugby’s best performing turf systems of the future.

As FieldTurf’s exclusive sports construction partner for England and Wales, we’re thrilled by the announcement. As a World Rugby Preferred Producer, we and our clients know first-hand that FieldTurf are a world leader in the production of artificial turf, trusted by top rugby teams such as Racing 92, Cardiff Blues, Stade Rochelais and US Oyonnax.

The launch of Scrum 2.0 and partnership with Gray marks the start of an exciting new chapter in rugby sports turf. Systems will be ‘engineered by the players, for the players’ with direct input from players, coaches and FieldTurf’s top technical experts.

In uncertain times, it’s great to be looking to the future, and we for one are very excited to see what’s ahead for sports surface innovation in rugby.

If you’d like to learn more about our partnership with FieldTurf and how we can deliver your rugby needs, please get in touch – or check out our case studies, such as our recent construction of the RFU Championship’s first artificial turf rugby pitch.